Materials Characterization

The following equipment is available to users of the Carleton Laboratory. For further details, click on the tab of the testing machine.

In order to use any of these testing machines, you must apply for Research Access, as described here.

The Columbia Nano Initiative Shared Laboratory Facilities (http://cni.columbia.edu/shared-labs) have additional materials characterization facilities that may be used be researchers.

Leco DH603 Hydrogen Analyzer

Hydrogen determinations are delivered quickly and precisely with the DH603 using diffusible and total hydrogen measurements. This robust instrument determines the amount of total hydrogen (or diffusible hydrogen) present in ferrous alloys. A small footprint, user-friendly operating software, increased instrument safety, and reliability are all part of the advanced DH603 design. The DH603 conforms to ISO Method 3690 "Ferritic Steel Arc Weld Metal" as a "Rapid Method" outlined in Sections 5.3.2.3 and 5.4.

SPECIFICATIONS

- Instrument range: 0.1 to 2500 ppm (for 1 g sample)

- Precision range: 0.02 ppm or 2% RSD, whichever is greater

- Readability: 0.001 ppm

SPECTROMAXx Spark OES

The SPECTROMAXx stationary metal analyzer is used mainly for material testing in foundries and for incoming and outgoing inspections in the metal industry around the world. It determines all of the elements used in the metal industry, including metal analysis of carbon, phosphorous, sulfur, and nitrogen.

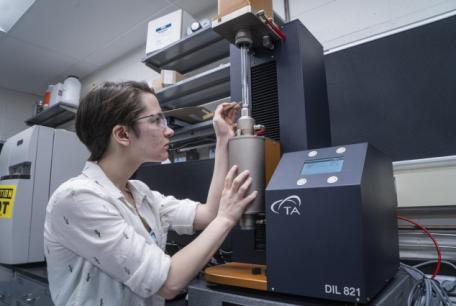

TA Instruments DIL 821

The TA Instruments DIL 821 is a cutting-edge vertical dilatometer that is especially useful in analysis of sintering, and studies in rate controlled sintering (RCS). Its vertical nature allows for samples to be analyzed that would be difficult to run in a horizontal dilatometer. It features an opical encoder with 1nm resolution and a linear motor capable of providing constant force throughout an experiement.

SPECIFICATIONS

- Sample Length: 0 to 25 mm

- Sample Diameter: 10 mm

- Material of Sample Holder: Fused Silica, Al2O3

- Contact Force: 0.01 to 1.0 N

- Change of Length: 5 mm

- Resolution ∆L°C: 1 nm, 0.5 °C

- Accuracy in α: 0.03 x 10-6K-1

- Atmosphere: Air

- Temperature Range: 23 °C to 1700 °C

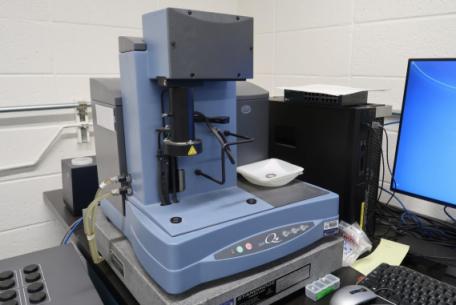

TA Instruments Q50 Thermogravimetric Analyzer

The rugged, reliable, and cost-effective TA Instruments Q50 TGA offers exceptional value as a compact, general-purpose thermogravimetric analyzer that typically out-performs competitive research-grade models. Its integral mass flow control, gas switching capability, superb software, and ease-of-use make the Q50 ideal in basic research and teaching.

The heart of the Q50 TGA is the accurate and reliable vertical thermobalance housed in a temperature-compensated environment. It uses the field-proven and industry-standard null-balance principle, which is free from the baseline complications also inherent in competitive designs. The Q50 balance provides the best accuracy and precision in weight change detection from ambient to 1,000°C, low baseline drift, and sensitive, reliable operation over the entire weight range.

An efficient horizontal purge gas system allows accurately metered purge gas to flow directly across the sample, and is expertly integrated into the vertical thermobalance/furnace design. A regulation portion of the gas is also directed through the balance chamber to eliminate backflow, and the combined gases plus any sample effluent exit the system by a side arm. The design minimizes buoyancy effects, and optimizes the removal of decomposition products from the sample area. The digital mass flow controllers improve data quality.

SPECIFICATIONS

- Maximum sample weight: 1 g

- Weighing precision: +/-0.01%

- Sensitivity: 0.1 µg

- Baseline dynamic drift: < 50 µg from 50 to 1,000°C at 20°C/min

- Temperature range: Ambient to 1,000°C

- Isothermal temperature accuracy: +/-1°C

- Isothermal temperature precision: +/-0.1°C

- Controlled heating rate: 0.1 to 100°C/min

- Furnace cooling (forced air, not controlled): 1,000°C to 50°C < 12 min

TA Instruments TAM Air Isothermal Calorimeter

Monitoring the thermal activity or heat flow of chemical, physical and biological processes provides information which cannot be generated with other techniques. Isothermal calorimetry is a powerful technique for studying heat production or consumption and is non-destructive and non-invasive to the sample. The TAM Air offers unmatched sensitivity and long-term temperature stability with flexible sample requirements. The TAM Air is the ideal tool for large scale calorimetric experiments, capable of measuring several samples simultaneously under isothermal conditions. This system is especially well-suited to processes that evolve or consume heat over the course of days and weeks such as cement and concrete hydration, food spoilage, microbial activity and more.

Determining the heat of hydration of cement and concrete is important and traditionally the heat of hydration has been determined by measuring the heat of solution (ASTM C186). More recently, isothermal calorimetry tests using TAM Air are favored because they accurately and reliably measure the heat of hydration (ASTM C1702) and predict the setting behavior of various cement mixtures. The samples tested in the TAM Air are often paste samples, where the cement hydration process can continuously be followed over time; it is also of importance to test not only the cement but also the final mixture of mortar or concrete. This allows for detection of incompatibility between the materials. The mixing effect on the same cement in a paste and in a concrete mixture will also be different as the aggregates will add to the shear forces.

Calorimetry requires little or no sample pretreatment; solids, liquids and gases can all be analyzed. When heat is produced in a sample, isothermal calorimetry measures the heat flow. The sample is placed in an ampoule that is in contact with a heat flow sensor that is also in contact with a heat sink. When heat is produced or consumed by any process, a temperature gradient across the sensor is developed. This will generate a voltage, which is measured. The voltage is proportional to the heat flow across the sensor and to the rate of the process taking place in the sample ampoule. This signal is recorded continuously and in real time. For each sample there is a reference that is on a parallel heat flow sensor. During the time that the heat flow is monitored, any temperature fluctuations entering the instrument will influence both the sample and the reference sensors equally. This architecture allows a very accurate determination of heat that is produced or consumed by the sample alone while other non-sample heat disturbances are efficiently factored out.

SPECIFICATIONS

- Number of simultaneous samples: 8

- Operating temperature range: 5°C to 90°C

- Thermostat stability: +/-0.02°C

- Maximum sample size: 20 mL

- Limit of detection: 4 µW

- Short term noise: < +/-2.5 µW

- Precision: +/-20 µW

- Baseline drift over 24 hours: < 40 µW

- Baseline deviation over 24 hours: < +/-10 µW

- Baseline error over 24 hours: < +/-23 µW

CARLETON LAB SERVICE CENTER RATES

Click the button below to view the rates for the Carleton Lab Service Center (Requires UNI login).

Columbia Nano Initiative

For more information about the shared labs of the Columbia Nano Initiative, please click on the button below.